Pretreatment filter

5μm, 1μm PP membrane is used for filtration, and the connection part adopts the company's unique design, which is convenient to disassemble and replace materials, and is beautiful.

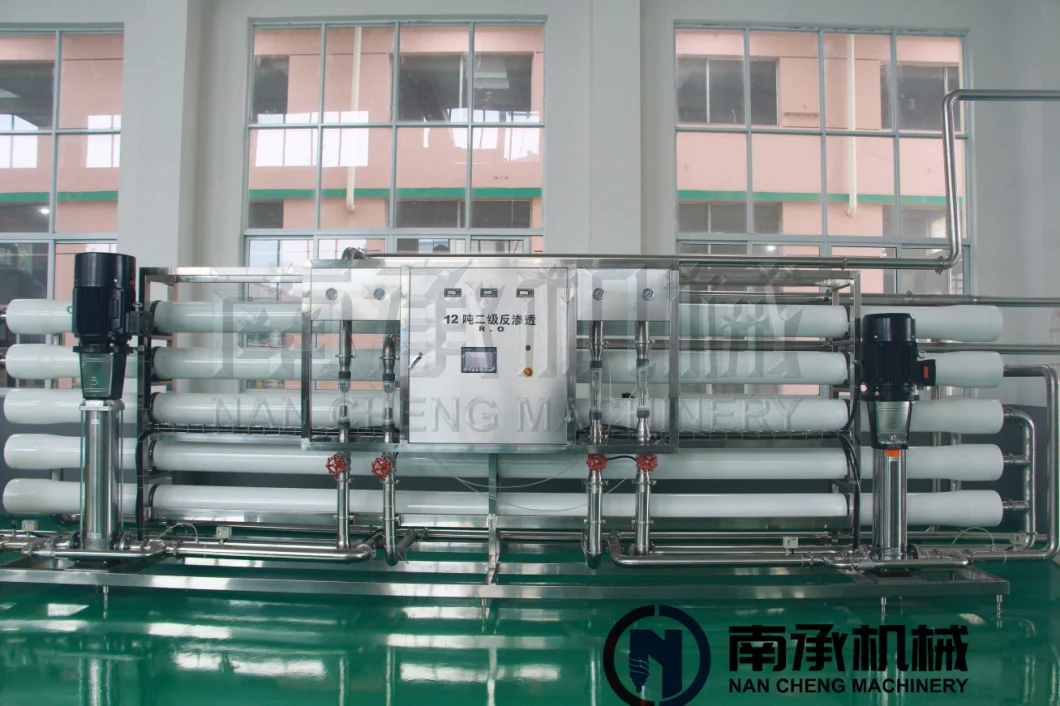

RO Reverse osmosis

How the Water Treatment and Bottling Plant Works

1.A semi permeable membrane in a reverse osmosis system only allows certain things to pass through.

2.This membrane passes water easily but also prevents many other contaminants from passing by trapping them.

3.Water is normally on both sides of the membrane, the water on each side has a different concentration of dissolved minerals.

4.The water in the less concentrated solution tries to dilute the more concentrated solution.

5.Water will pass through the membrane from the lower concentration side to the greater concentration side.

6.The osmotic pressure (see diagram) created by the difference in water levels, will counter the diffusion process forming an equilibrium between the two sides.

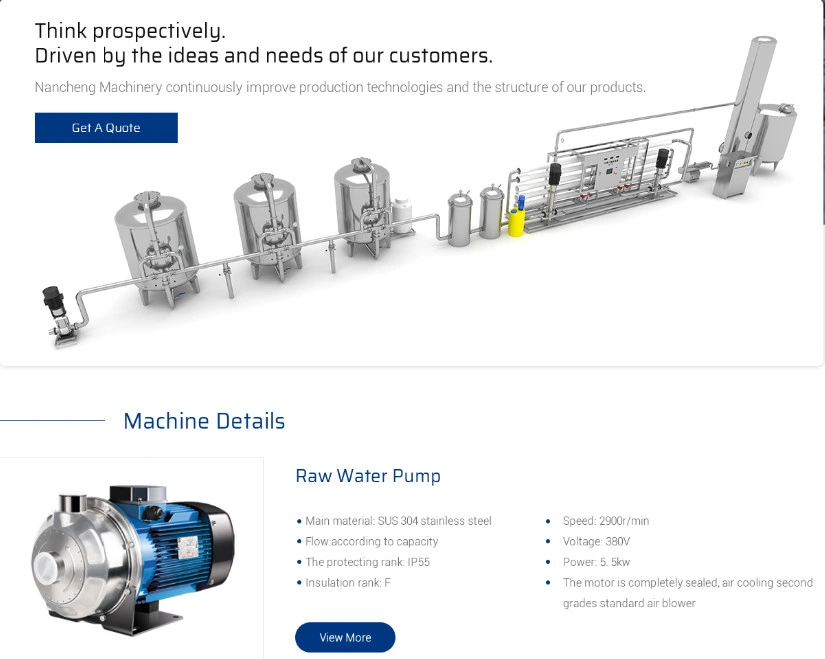

Water Treatment and Bottling Plant Technical route and flow diagram instructions

The technical route is as following:

Raw tank-->Booster pump -->Quartz sand filter-->activated carbon filter--->Anti-scalant dosing-->Sediment filter-->High pressure pump-->Reverse osmosis desalination device-->Permeate tank

Materials of Construction

Skid Frame: SS304

Membrane Elements:Hydraulics CAP3-8040

Membrane Housings: SS304

Low pressure piping: SS304

High pressure piping: SS304

Pump and Motor

Pump: 304SS vertical multi-stage centrifugal

Motor: TEFC, 380/460 VAC, 3-phase, 50/60 Hz.

Standard Features

8" x 40" High rejection membrane elements

5-micron sediment pre-filter housing

Automatic inlet solenoid valve

PLC control

Product water conductivity monitor

Operating pressure gauges

Product and concentrate flow meters

Concentrate and recycle flow control valves

Low inlet pressure switch with shutdown alarm

Auto/Manual wash

Capacity:500-50000Liter per Hour

SS304 construction

USA Brand Hydraulics membrane

SS304 membrane housing

SS304 piping and fitting

Multi-stage SS304 high-pressure centrifugal pump

Schneider,Siemens electronic parts

Nominal Recovery:65-75%

Nominal Salt Rejection:99.60%

Auto/Manual backwash

Low inlet pressure switch with shutdown alarm

Option:Ozone generator,UV,Storge tank etc.

UV sterilizer

Pure water tank

Design Basis:

1. Raw water analysis report (provided by customer)

2. JB2932<Specification for water treatment equipment>JB2932

3. CD130A16<Specification for rubber lining equipment>CD130A16

4. CD130A15<Technical regulation for design of rubber lining equipment>CD130A15

5. GB17323<Hygienic standard of bottled purified water for drinking>GB17323

6. GB17324< Hygienic standard of bottled purified water for drinking >GB17324

7. RO membrane elements manufacturer (RO design guidelines)

Note:

The water analysis report should be provided with signature and stamp by user. And it will be the design basis of this project.

;

Above technical parameters and water quality report which is provided by customer i s the basic data of this prorosal.

Any adjustment to these data,will lead the change of equipment model and configuration.

If the water source used actually has bigger difference from the index in the analysis report for designing the proposal or water source type changes,

other equipment contract will need to be added by the user.

RO membrane capacity test conditions(provided by RO membrane supplier): 2000ppm NaCl,15. 5bar,25ºC,PH8,15% Recovery;

Single-vessel membrane permeate f low may be different, but the deviation won't exceed 7%of the value listed.

When water temperature decreases 10ºC,RO permeate flow will decrease by 10~20%

How the Water Treatment and Bottling Plant Works

1.A semi permeable membrane in a reverse osmosis system only allows certain things to pass through.

2.This membrane passes water easily but also prevents many other contaminants from passing by trapping them.

3.Water is normally on both sides of the membrane, the water on each side has a different concentration of dissolved minerals.

4.The water in the less concentrated solution tries to dilute the more concentrated solution.

5.Water will pass through the membrane from the lower concentration side to the greater concentration side.

6.The osmotic pressure (see diagram) created by the difference in water levels, will counter the diffusion process forming an equilibrium between the two sides.

Water Treatment and Bottling Plant Technical route and flow diagram instructions

The technical route is as following:

Raw tank-->Booster pump -->Quartz sand filter-->activated carbon filter--->Anti-scalant dosing-->Sediment filter-->High pressure pump-->Reverse osmosis desalination device-->Permeate tank

Materials of Construction

Skid Frame: SS304

Membrane Elements:Hydraulics CAP3-8040

Membrane Housings: SS304

Low pressure piping: SS304

High pressure piping: SS304

Pump and Motor

Pump: 304SS vertical multi-stage centrifugal

Motor: TEFC, 380/460 VAC, 3-phase, 50/60 Hz.

Standard Features

8" x 40" High rejection membrane elements

5-micron sediment pre-filter housing

Automatic inlet solenoid valve

PLC control

Product water conductivity monitor

Operating pressure gauges

Product and concentrate flow meters

Concentrate and recycle flow control valves

Low inlet pressure switch with shutdown alarm

Auto/Manual wash

Capacity:500-50000Liter per Hour

SS304 construction

USA Brand Hydraulics membrane

SS304 membrane housing

SS304 piping and fitting

Multi-stage SS304 high-pressure centrifugal pump

Schneider,Siemens electronic parts

Nominal Recovery:65-75%

Nominal Salt Rejection:99.60%

Auto/Manual backwash

Low inlet pressure switch with shutdown alarm

Option:Ozone generator,UV,Storge tank etc.

Optional Equipment Available

Atmospheric storage tanks with level control and repressurization pump

Pressurized storage vessels

UV

Ozone generator

Membrane clean-in-place (CIP) systems

Pretreatment chemical injection systems

| Model | Production of water (Ton/h ) | Motor power (kw) | Membrane | Entrance Diameter (mm) | Size(L*W*H) ( cm) | Weight(Kg) |

| RO-0.5 | 0.5 | 1.1 | 4040 | 32 | 170*70*170 | 200 |

| RO-1 | 1 | 1.5 | 4040 | 32 | 155*90*180 | 200 |

| RO-2 | 2 | 3 | 4040 | 38 | 480*70*200 | 300 |

| RO-3 | 3 | 4 | 8040 | 48 | 470*100*230 | 400 |

| RO-4 | 4 | 5 | 8040 | 48 | 470*100*230 | 450 |

| RO-5 | 5 | 7 | 8040 | 60 | 500*120*230 | 600 |

| RO-10 | 10 | 11 | 8040 | 60 | 900*200*200 | 800 |

| RO-15 | 15 | 16 | 8040 | 72 | 1000*187*300 | 1000 |

| RO-20 | 20 | 30 | 8040 | 60 | 1000*180*400 | 1550 |